-

Established in 2020, Draking Semiconductor was jointly founded by the core team of a leading Chinese semiconductor listed company and core technical personnel from world-leading companies.

-

-

The company has assembled a strong R&D and process team, continuously improving in aspects such as diamond powder material selection and dispersion, electroplating technology, precision processing technology, and adhesive formulation.

-

Draking Semiconductor Technology can perform dicing on chips such as IGBT chips, SiC chips, lithium tantalate/lithium niobate chips, integrated circuit IC chips, and double-bonded chips, as well as on packages such as QFN and DFN, and ceramic and glass substrates.

-

-

Product Center

Wafer Dicing Services

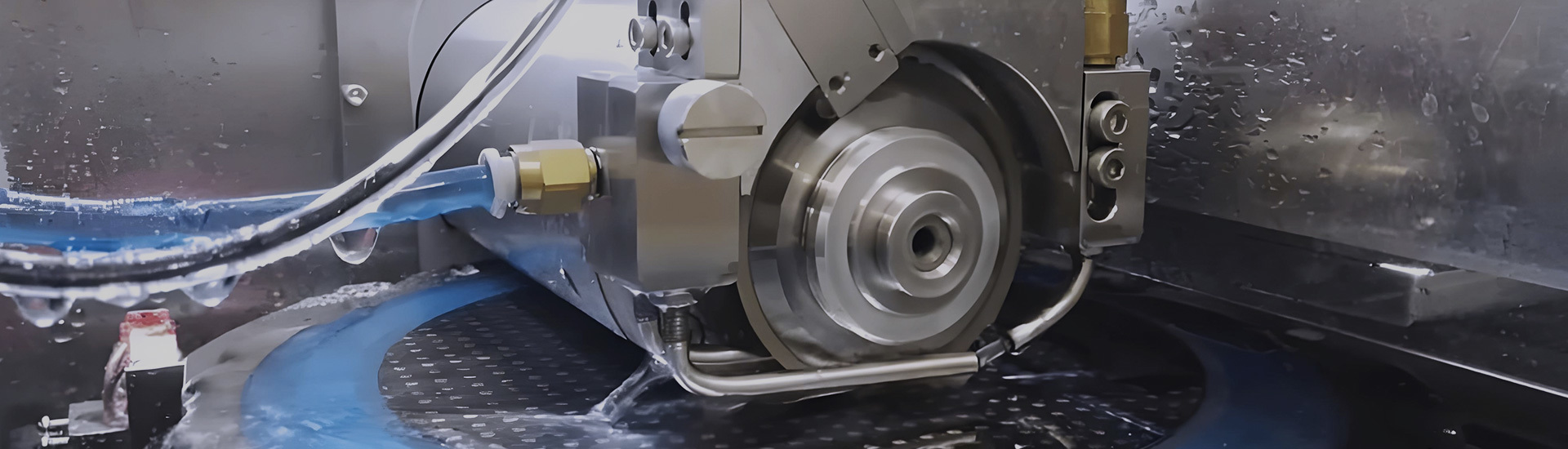

OverviewDraking Semiconductor Technology started its chip packaging lapping and scribing business in 2023. The company has an 800-square-meter class 1000 cleanroom for lapping and scribing operations, equipped with a professional application technology team. Through professional teams, equipment, and consumables, it provides lapping and scribing processing services for packaging customers and IC design customers. Currently, it has established mature processes for wafer front-side film lamination, back-side thinning (polishing), wafer dicing, and processing of packaging bodies/ceramic substrates/glass/magnetic materials. |

Processable Materials(1) Silicon wafers: ESD, TVD, MOS, IGBT, IC, LED, etc.; (2) Compound semiconductors: Silicon carbide, lithium tantalate, lithium niobate, gallium nitride, etc.; (3) Others: QFN/DFN, ceramic substrates, quartz, glass, etc. |

EquipmentThe company boasts strong equipment capabilities. (1) Dicing saws: 20 dual-axis automatic dicing saws, models DISCO 6361/6340 and TSK 3000T; (2) Backgrinding machines: 2 high-configuration backgrinding machines, models DISCO 8761/8540, with complete auxiliary equipment. |

Processing CapacityThe company's current monthly output is 60,000-80,000 wafers of various types, and there is capacity for 8-10 more machines to handle increased business. |

Fill out the form, and we will provide you with a suitable customized solution

If you have any requirements, please leave your information and click the button on the right to fill out your requirements

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Telephone

Ms. Chen +86-19946171465

Mr. Wang +86-19101627797

Address

Building 2, Jinhui Technology Park, No. 3119, Mudanjiang West Road, Qidong City, Jiangsu Province, China.