-

About UsEstablished in 2020, Draking Semiconductor was jointly founded by the core team of a leading Chinese semiconductor listed company and core technical personnel from world-leading companies.

-

-

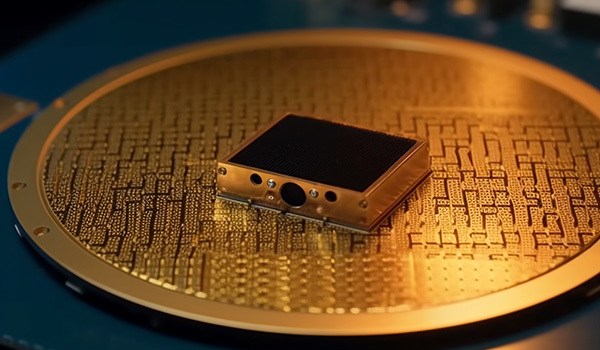

TechnicalThe company has assembled a strong R&D and process team, continuously improving in aspects such as diamond powder material selection and dispersion, electroplating technology, precision processing technology, and adhesive formulation.

-

SolutionsDraking Semiconductor Technology can perform dicing on chips such as IGBT chips, SiC chips, lithium tantalate/lithium niobate chips, integrated circuit IC chips, and double-bonded chips, as well as on packages such as QFN and DFN, and ceramic and glass substrates.

-

-

Pre-sales, One-stop Solution Provider

Customers provide sample chips/edge chips, and the company will conduct cutting process tests at its own grinding and dicing plant to provide customers with suitable dicing blade and cutting process parameter solutions, so that customers can seamlessly start production after obtaining the dicing blade; subsequently, the company will provide customers with a complete cutting solution of dicing blade + dicing machine + cutting process parameters.

Advanced Production Process Management

Data linkage

From the beginning of production material input,

Unique coding identification of products,

Closed-loop system control of the entire production process

Production Workshop

1000 square meters of class 1000 cleanroom

5,000 square meters factory

Japan High-tech R&D Center

Production equipment

Automated production line, reducing human disturbance

Imported high-precision processing equipment from Japan,

Chemical process equipment and testing equipment

Fine control

Japanese precision production management system

Production management team with rich industry experience

Comprehensive Testing Quality Control System

Strict testing standards

The testing standards are measured in μm, and the control is strict;

The highest testing standard is based on the end customer's usage standard, and

Based on self-owned facilities, random checks of full cutting are simulated in the customer's production environment,

To verify product quality and performance.

Complete inspection process

Dozens of inspection processes in the production process, full inspection of product results;

Control product quality and reduce loss costs;

Customer complaint traceability, one code to the end.

High-end testing equipment

Equipped with Keyence SEM electron microscope, concentricity measuring instrument, thickness measuring instrument,

and flatness measuring instrument, particle size analyzer,

Nikon high-magnification microscope, roughness measuring instrument,

Hardness measuring instrument, Leco carbon analyzer, etc.

After-sales, Timely and Comprehensive Worry-free

Product delivery actively responds to customer needs,

Short delivery cycle

Respond to product and technical issues in real time,

Provide on-site and online support

Dissatisfied,

Provide worry-free return and exchange services

Fill out the form, and we will provide you with a suitable customized solution

If you have any requirements, please leave your information and click the button on the right to fill out your requirements

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Telephone

Ms. Chen +86-19946171465

Mr. Wang +86-19101627797

Address

Building 2, Jinhui Technology Park, No. 3119, Mudanjiang West Road, Qidong City, Jiangsu Province, China.